The purpose of this technical data is to provide assistance in selecting and detailing EPS-3D ICF Structural Panels.

The information presented herein includes our typical details and design guidelines. Our Engineering Department will prepare shop drawings and calculations based on your final plans and specifications.

Sales and Engineering personnel are available to assist you with optimum panel layouts, details, finish selections and budgets. Please contact us.

Although care has been taken to provide the most accurate data possible, Milestone Ventures, does not assume responsibility for errors and omissions.

Introduction

The purpose of this technical data is to provide assistance in selecting and detailing EPS-3D ICF Structural Panels manufactured by Interform.

The information presented herein includes our typical details and design guidelines. Our Engineering Department will prepare shop drawings and calculations based on your final plans and specifications.

Milestone Ventures, Sales and Engineering personnel are available to assist you with optimum panel layouts, details, finish selections and budgets. Please contact us.

Although care has been taken to provide the most accurate data possible, Milestone Ventures, does not assume responsibility for errors and omissions.

Features

- Workability

- Monolithic

- Lightness

- Handling

- Simplicity

- Savings

- Auto-construction

- Speed

- Comfort

- Resistance

- Durability

- Maintainability

- Biocompatibility

- LESSER SLAB WEIGHT

- HIGHLY ENERGY EFFICIENT

- SOUND PROOF

- FIRE RESISTANCE

STRUCTURAL THEORY

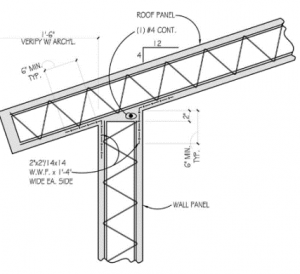

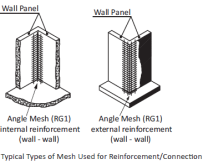

Milestone Ventures EPS-3D ICF Structural Panels far surpass the strength of conventionally framed structures. These panels are very strong when loaded axially (wall panel) because they perform as a composite column. The rigid foam steadies the relatively flexible skins over every square inch of their surface to prevent them from buckling. Figure 2A illustrates this effect.

Panels are also very strong in bending such as when a wall is under a wind load, or a roof panel is

loaded with a heavy layer of snow. In bending, a panel behaves like an I-beam with very wide

flanges and a web as thick as the panel is wide (Figure 2B). The skins act like the flanges by

carrying the resultant compressive and tensile stresses. The core acts like the web by resisting shear forces and providing continuous support to the skins to prevent them from buckling and wrinkling. In special applications, Interform’s injection process makes it possible to mold a variety of structural elements, such as laminated beams inside the panels for additional support.

Definitions

Galvanised Steel Mesh

Panels

Weight

Compared with the traditional prefabricated structure, the EPS SYSTEM panels have an inferior weight.

| Slab type | Thickness 20 cm | Thickness 24 cm | Thickness 28 cm |

|---|---|---|---|

| EPS | 175 Kg/m² | 193 Kg/m² | 211 Kg/m² |

| Concrete and hollow bricks |

260 Kg/m² | 280 Kg/m² | 320 Kg/m² |

| Slab predalles | 320 Kg/m² | 350 Kg/m² | 380 Kg/m² |

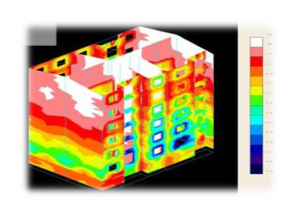

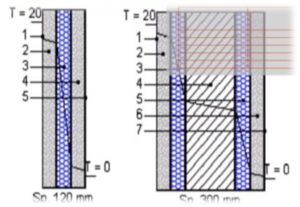

THERMAL INERTIA

The values of transmittance of the walls EPS are significantly better than those achieved by traditional plaster walls

| Element type | Micro concrete thickness (cm) |

EPS thickness (cm) |

Total thickness (cm) |

Transmittance thickness (cm) |

|---|---|---|---|---|

| Double panel | 3,5 + 15 + 3,5 | 5 + 5 | 32 | 32 |

| Single panel | 2,5 + 15 + 2,5 | 8 + 8 | 36 | 36 |

| Single panel | 3 + 3 | 8 | 14 | 14 |

| Single panel | 3 + 3 | 12 | 18 | 18 |

| Single panel | 3 + 3 | 16 | 22 | 22 |

| CLS wall | 27 | 27 | ||

| Double wall board | 19 | 30 | 30 | |

| CLS block wall | 2,70 | 2,70 |

ACOUSTIC INERTIA

The values of sound insulation of walls EPS are comparable to those of masonry built with traditional systems.

| Element type | Micro concrete thickness (cm) |

EPS thickness (cm) |

Total thickness (cm) |

Insulation (dB) |

|---|---|---|---|---|

| Double panel | 3 + 14 + 3 | 5 + 5 | 30 | 37 |

| Single panel with | 3,5 + 3,5 | 8 | 15 | 37 |

| Diathionite plaster | ||||

| Hollow board | 11 | 37 | ||

| Double wall plank | 30 | 44 |

FIRE RESISTANCE

The values of emission of carbon monoxide produced during combustion are significantly lower compared to their naturally flammable materials.

| Element type | Combustion temperature (°C) |

Carbon monoxide (PpM) |

|---|---|---|

| EPS | 600 | 1.000 |

| Wood fiber | 600 | 69.000 |

| Wood | 600 | 15.000 |

| Cork | 600 | 29.000 |

COMFORT

The panel can be sized to achieve the welfare conditions of thermo- hygro and acoustic required by the different climatic conditions.

RESISTANCE

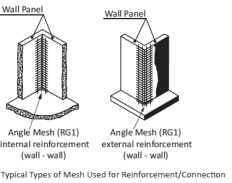

The wire mesh incorporated in the CLS and patented technologies for the implementation of the panels offer greater resistance to nodes in the event of structural static actions such as seismic.

Elements

PANELS

- SINGLE

- DOUBLE

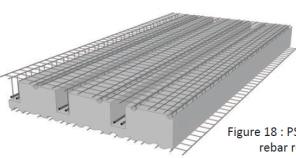

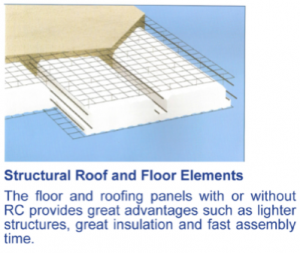

- SLAB

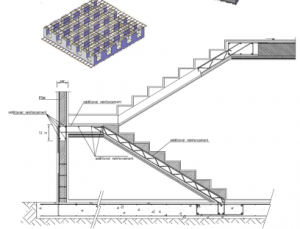

- STAIRWAY

MATERIALS

Steel

Sintered expanded polystyrene (EPS)

Concrete

Structural plaster

STEEL

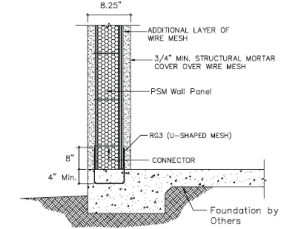

External meshes and connectors are made of drawn steel wire, hot galvanized, low carbon, welded for electro fusion, having a high threshold of breakage.

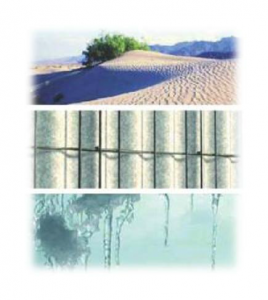

EXPANDED POLYSTYRENE SINTERED (EPS)

The raw material comes in glassy Granules, obtained by the polymerization of styrene, a liquid compound of carbon and hydrogen. The granules are expanded in two Phases to obtain blocks of density Between 15 and 25 kg/m³, composed of 2% of the beads and 98% air.

FEATURES EPS (1/3)

Isotropic

Storage time capacity insulation

Resistance to temperature change

Low water absorption by immersion

No water absorption by capillarity

Imputrescibility

Dimensional stability

Non-toxic

Low heat absorption

Easy processability

Recyclability

Transportability

FEATURES EPS (2/3)

WATER RESISTANCE

The EPS is waterproof. The water does not dissolve the EPS and is only minimally absorbed in the interstices between the granules residues. Absorption by capillarity is zero, as well as the absorption of humid air.

DURATION AND ENVIRONMENTAL SAFETY

The EPS is stable chemically and biologically. Not support the growth of microorganisms, mold or fungi, therefore, does not rot Does not constitute danger of environmental pollution during production or application. Vouch for an unlimited period of performance required

FEATURES EPS (3/3)

FIRE RESISTANCE

EPS normal combustible; decomposition occurs at about 230 to 260 °C with release of flammable vapors, but only 450 500 °C we have the ignition. EPS suitably treated with additives, flame spread ceases to be less the case of initiation. The EPS burns only if exposed, in a fire generates only 8% of the heat emitted by an equal volume of wood in a fire and spread to a quantity of toxic gases (carbon monoxide) even less.

RESISTANCE TO WATER VAPOR

The EPS, impermeable to water, is permeable to water vapor and therefore breathable, this means that in isolated environments with EPS mold and mildew is not formed.

FEATURES EPS (3/3)

Proceeds from the cavity of double panels.

Grain size between 0 and 12 mm.

A maturity will have a minimum strength of 35 N / mm ².

Composition per m³:

| Cement | 450 Kg |

|---|---|

| Sand; | 1550 Kg |

| Water | 160 l |

COAT

Spray applied (spritz beton) on each side the panel to a thickness of 3.5 cm.

Grain size between 0 and 1.5 mm.

A maturity will have a minimum strength of 25 N/mm ².

Composition per m³:

| Cement | 350 Kg |

|---|---|

| Sand; | 1600 Kg |

| Water | 160 l |

MECHANICAL STRENGTH

STATIC

The panels, with their weight ranging between 4 and 15 kg / m², remain light to the installation, after the assembly is applied the concrete that incorporates the complete meshes and the static function of the artifact, ensuring a high resistance operating

SEISMIC

The presence of wire mesh panels and structural nodes ensures high resistance to seismic actions.

THERMAL RESISTANCE

The EPS has high insulating properties. The low thermal conductivity is due to the structure of the material, consisting of 98% air trapped in cells of a size to prevent convective movements.

SOUND RESISTANCE

The presence of EPS offers a high degree of acoustic insulation

FIRE RESISTANCE

The EPS is poorly flammable; requires a volume of combustion air equal to 150 times its volume so the fire can destroy it completely. If protected by two layers of concrete, as the panel put in place, can not burn.

RESISTANCE TO LIGHTNING

Galvanized steel meshes on the façade panel EPS contribute to a metallic structure similar to a Faraday cage, which can provide protection

against lightning

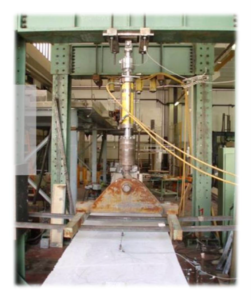

TESTS

MECHANICAL

THERMAL

ACOUSTIC

FIRE RESISTANCE

MECHANICAL TESTS

Load-bearing characteristics of the panels were determined experimentally by testing to failure in order to identify the resistance last of the structure:

Centered compression

Eccentric compression

Diagonal compression

Sliding

Deflection

Cyclic deflection

Impact with mild body

Ballistic impact

Static

CENTERED COMPRESSION

The tests are performed on slabs of size 112270 cm, formed by a layer of EPS in varying thickness coated with two layers of screed thickness 3.5 cm. The slabs are placed vertically and centrally loaded.

| Total thickness (cm) |

EPS thickness (cm) |

Tensile strength (KN) |

|---|---|---|

| 15 | 8 | 701 |

| 19 | 12 | 806 |

| 23 | 16 | 855 |

ECCENTRIC COMPRESSION

The tests are performed on slabs of size 112270 cm, formed by a layer of EPS in varying thickness coated with two layers of screed thickness 3.5 cm. The slabs are placed vertically and loaded on the centerline of one of the two layers of screed.

| Total thickness (cm) |

EPS thickness (cm) |

Tensile strength (KN) |

|---|---|---|

| 15 | 8 | 375 |

| 19 | 12 | 460 |

| 23 | 16 | 524 |

DIAGONAL COMPRESSION

The tests are performed on slabs of dimensions 112x112x15 cm, formed by a layer of EPS of 8 cm thick covered with two layers of screed thickness 3.5 cm.

| Prestress (KN) |

First crack load (KN) |

TBreakage load (KN) |

|---|---|---|

| 144 | 302 | |

| 30 | 129 | 342 |

| 90 | 118 | 332 |

| 168 | 306 |

GLIDING

Tests are performed on samples of size 4045, 5 cm made of three layers of screed of uniform thickness and two layers of EPS of variable thickness, loaded at the central layer of screed.

| Total thickness (cm) |

EPS thickness (cm) |

Max shift (mm) |

Breakage load (KN) |

|---|---|---|---|

| 31 | 8 | 4 | 25 |

| 39 | 12 | 6,5 | 15 |

| 47 | 16 | 5,5 | 12 |

BENDING

The tests are performed on slabs of varying sizes, made of two layers of4 cm thick screed constant and a central layer of EPS of variable thickness. The plates are placed horizontally and loaded in the middle.

| Dimensions (cm) |

Total thickness (cm) |

EPS thickness (cm) |

Maximum fall (mm) |

First crack load (KN) |

Breakage load (KN) |

|---|---|---|---|---|---|

| 300112 | 16 | 8 | 56 | 4 | 19,6 |

| 300112 | 16 | 8 | 72 | 3,7 | 18,5 |

| 400112 | 20 | 12 | 67 | 2,4 | 14,4 |

| 400112 | 20 | 12 | 75 | 2 | 14,9 |

| 500112 | 24 | 16 | 67 | 2,2 | 14,1 |

| 500112 | 24 | 16 | 60 | 1,4 | 13 |

CYCLICAL BENDING

The tests are performed on samples formed of a vertical panel size 112x270x15 cm, on which is grafted at mid-height a slab panel of dimensions 112x44x16 cm. The slab panel is subjected to loads directed alternately upward (positive) and down (negative).

| Sample N° | First crack load (KN) |

Breakage load (KN) |

|---|---|---|

| 1 | 1,34 | 4,89 |

| -2,10 | -5,80 | |

| 2 | 1,40 | 3,02 |

| -1,45 | -3,40 |

BALLISTIC IMPACT

The tests are performed on a panel of size 112x112x13 cm, consisting of two layers of screed thickness 4 cm and a central layer of 5 cm thick EPS. Placed vertically on the panel is shot multiple times a body size equal to 5.1 x10, 2 cm, weight 4 kg.

| Impact N° | Speed Impact (Km/h) |

Depth of impact (mm) |

Impact area (mm) |

|---|---|---|---|

| 1 | 56 | 40 | |

| 2 | 113 | 60 | 80105 |

| 3 | 161 | 50 | 6095 |

| 143 | 60100 |

STATIC LOAD

- Tests performed at the collapsed roof of a building prototype

- Walls made of individual panels consist of:

two layers of screed thickness 3.5 cm

central layer of thickness 8 cm EPS

total thickness of 15 cm

- Slab coverage made of single panels formed of:

two layers of screed thickness 5 cm and 3 cm

EPS central layer of thickness 12 cm

total thickness of 20 cm

- Mechanical strength screed : 25 N/mm²

- Yield strength welded mesh : 700 N/mm²

- First crack load : 820 Kgf/m²

- Collapse load : 2000 Kgf/m²

THERMAL TEST

The tests are performed on single and double panels in the following conditions:

Outside temperature = 0 °C

Indoor temperature= +20 °C

| Element type | Micro concrete thickness (cm) |

EPS thickness (cm) |

Total thickness (cm) |

Transmittance (W/m²K) |

|---|---|---|---|---|

| Double panel | 3,5 + 15 + 3,5 | 5 + 5 | 32 | 0,44 |

| Single panel | 2,5 + 15 + 2,5 | 8 + 8 | 36 | 0,35 |

| Single panel | 3 + 3 | 8 | 14 | 0,58 |

| Single panel | 3 + 3 | 12 | 18 | 0,40 |

| Single panel | 3 + 3 | 16 | 22 | 0,30 |

ACOUSTIC TESTS

The test environment consists of a bedroom and a double channel receiver, separated by panels to EPS. The tests are carried out as follows:

Frequency of emission = 500 Hz

Sound pressure issuer = 87 dB

| Element type | Micro concrete thickness (cm) |

EPS thickness (cm) |

Total thickness (cm) |

Insulation (dB) |

|---|---|---|---|---|

| Double panel | 3 + 14 + 3 | 5 + 5 | 30 | 37 |

| Single panel with Diathionite plaster |

3,5 + 3,5 | 8 | 15 | 37 |

FIRE RESISTANCE TEST

The panels have excellent fire resistance values

| Element type | Micro concrete thickness (cm) |

EPS thickness (cm) |

Total thickness (cm) |

|---|---|---|---|

| Double panel | 3,5 + 15 + 3,5 | 5 + 5 | 32 |

| Single panel | 3,5 + 3,5 | 8 | 15 |

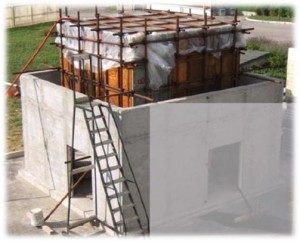

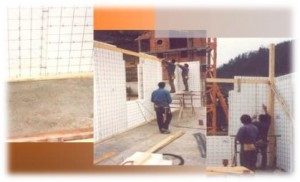

CONSTRUCTION

CONSTRUCTION PHASES

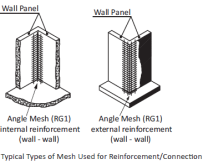

Jet foundation bed

Inclusion of irons anchor

Transportation of the panels on site

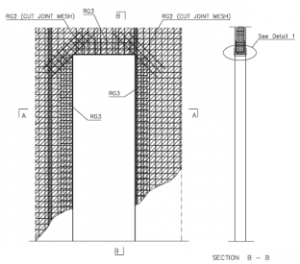

Installation of perimeter panels

Realization of openings

Postage of wire mesh

The shores of the perimeter walls

Proceeds of CLS interspace

Implementation of internal partitions

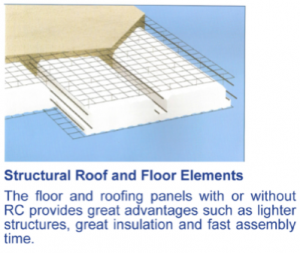

Implementation of Slab

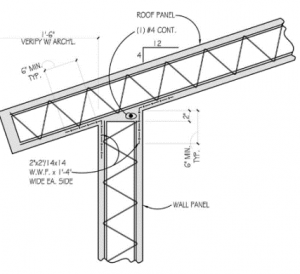

Implementation covers

Accommodation facilities

Application of spritz-beton

Finishing walls

Shaving walls

Completion of the building

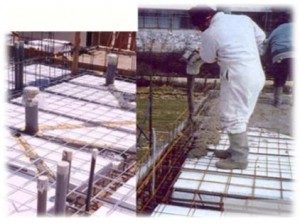

STEP 1

Jet foundation bed Inserting needles anchor Transportation of the panels on site

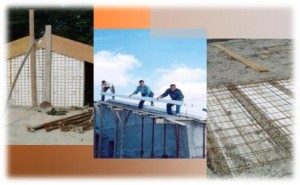

STEP 2

STEP 3

Postage mesh Predisposition for the slab panel

STEP 4

Temporary plugging of the window edges Shoring of the perimeter walls Shot CLS interspaces perimeter panels

STEP 5

Completion of the perimeter walls Implementation of internal partitions.

STEP 6

Realization of the slabs Shot CLS integrative sunroofs.

STEP 7

Covers realization Shot CLS supplemental coverage.

STEP 8

Facilities accommodation Coating panels with integrative cast concrete.

STEP 9

Finishing walls.

STEP 10

Shaving walls Completion of the building.

EPS Construction is similar to convention construction just the building block is

EPS rather than concrete blocks or bricks. Any kind of construction is possible

Energy Efficient Low Cost Housing Schools & Hospitals

The 200 underprivileged regions are situated in 27 out of Indonesias 33 provinces, with East Nusa Tenggara to host the largest number of the houses 1,440 followed by Papua with 1,260 houses. Helmy said he expected even a larger number of low-cost houses to be built in underdeveloped regions next year, including in Indonesias outermost islands, estimated to be inhabited by 20,000 families.

By the end of 2013, we hope 100 percent of the outermost islands become free from shabby houses, he said upon signing the MoU.

Djan, meanwhile, said his ministry was developing a total of 60,000 houses this year, which fell short the 4.8 million needed.

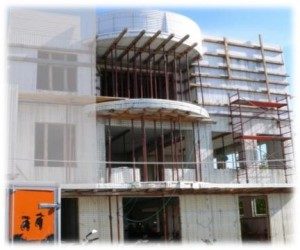

BUILDINGS

- RESIDENTIAL

- OFFICES

- HOTELS

- CEMALLS

- INDUSTRIAL COMPLEX

RESIDENTIA

RESIDENTIAL